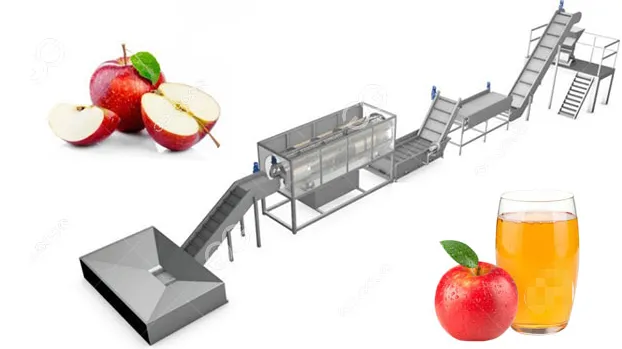

Apple Juice Pressing Equipment

Turning fresh apples into high-quality juice is more than just squeezing the fruit; it’s a delicate process requiring specialized machinery. For manufacturers planning or upgrading production lines, understanding the individual functions and capabilities of each machine, especially the apple juice press, is crucial for ensuring efficiency, safety, and flavor consistency. Let’s walk through the process.

- Washing and Sorting System

This entire process involves cleaning the apples and selecting the best quality ones.

A bubble washer and brush scrubber remove dirt and residue from the apples. A sorting conveyor then removes bruised or damaged fruit, ensuring only the best quality apples continue on.

- Pressing and Grinding

Before pressing, the apples are ground into a fine puree. A fruit crusher then crushes the apples. This continuous grinding ensures a higher juice yield during the pressing process, preparing them for juicing.

- Apple Juice Pressing Equipment—The Core of the Process

Note: This is the core of the production line. Apple juice pressing equipment includes belt presses, hydraulic juicers, and screw presses. These machines efficiently extract juice while separating the pomace, preserving the apple’s natural aroma and nutrients.

- Enzyme Treatment and Clarification (Optional)

For producers seeking clear or filtered juice, clarification systems can improve clarity and stability, resulting in a more refined taste.

- Filtration

For a smoother mouthfeel: Plate or membrane filtration systems remove fine particles, improving clarity without compromising taste.

- Pasteurization Equipment

Food safety cannot be compromised. Plate or tubular pasteurizers briefly heat the juice to kill microorganisms while preserving its natural flavor.

- Filling and Packaging Machines

After pasteurization, the juice is ready for packaging. Automated filling lines support hot-fill, cold-fill, or aseptic packaging. They are suitable for bottle, carton, or bag-in-box systems.