Apple juicing equipment is a core component of any fruit juice processing operation. Whether you’re running a small juice workshop or a large-scale beverage factory, having the right equipment ensures efficient production, high juice yield, and consistent product quality.

This article explores the different types of apple juicing equipment, their functions, and key factors to consider when selecting machines for your juice processing line.

What Is Apple Juicing Equipment?

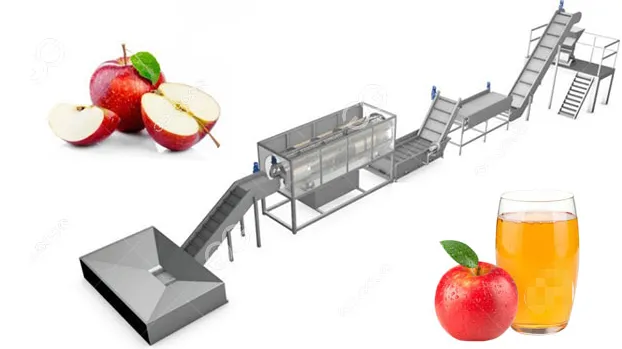

Apple juicing equipment refers to a complete set of machinery used to extract juice from fresh apples and process it into finished juice products. This equipment can include everything from washing systems and crushers to juice extractors, filtration units, and packaging machines.

The goal is to streamline the juicing process, maintain hygiene standards, and optimize output for commercial use.

Core Components of an Apple Juice Processing Line

A typical apple juicing equipment line includes the following key machines:

1. Apple Washing Machine

- Removes dirt, dust, and pesticide residues from raw apples.

- Often equipped with bubble or spray systems for gentle but effective cleaning.

2. Fruit Crusher / Mill

- Chops or grinds apples into smaller particles or mash.

- Prepares the fruit for efficient juice extraction.

3. Juice Extractor / Press

- The central machine in the line.

- Types include belt presses, hydraulic presses, and screw presses.

- Designed to separate juice from the pulp with high extraction efficiency.

4. Juice Filter and Clarifier

- Removes solids, fibers, and particles from the raw juice.

- Ensures clarity and improves shelf life.

5. Pasteurizer

- Heats the juice to kill harmful microorganisms.

- Maintains flavor and nutritional value while ensuring food safety.

6. Filling and Packaging Machine

- Automatically fills juice into bottles, pouches, or cans.

- Seals and labels products for distribution.

Benefits of Modern Apple Juicing Equipment

- ✅ High Juice Yield: Advanced presses and filters help maximize extraction from raw materials.

- ✅ Automation: Many machines offer programmable control for reduced labor and consistent output.

- ✅ Hygienic Design: Made from food-grade stainless steel, easy to clean and compliant with HACCP standards.

- ✅ Energy Efficiency: Modern systems are designed for low energy consumption with high performance.

- ✅ Modular Design: Equipment can be customized or scaled based on production needs.

Choosing the Right Apple Juicing Equipment

When selecting equipment for your apple juice business, consider the following:

- Production Capacity: Match equipment size and speed to your daily output.

- Juice Type: Clear juice, cloudy juice, or cider—different processes may apply.

- Space Availability: Choose compact or modular designs if working with limited space.

- Maintenance Needs: Look for machines with easy-to-clean features and low maintenance requirements.

- Budget and ROI: Evaluate upfront cost vs. long-term efficiency and productivity.

Application Fields

- 🍎 Apple juice and cider production factories

- 🍏 Fruit and vegetable processing plants

- 🧃 Beverage manufacturing companies

- 🏭 Food and agricultural cooperatives

- 🛒 Supermarkets or juice brands with in-house production lines