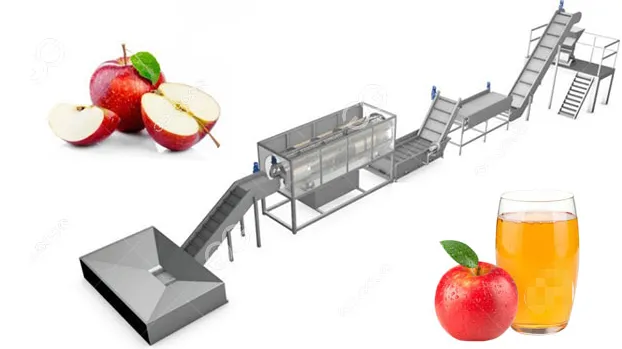

Apple juice manufacturing is a carefully controlled industrial process that transforms fresh apples into a stable, safe, and consistent beverage while preserving flavor, color, and nutritional value. Unlike small-scale juicing, commercial apple juice production requires precise handling of raw materials, enzymatic treatment, clarification, thermal processing, and hygienic filling systems.

This article explains the apple juice manufacturing process step by step, focusing on industrial best practices and quality control.

1. Raw Apple Selection and Incoming Inspection

The quality of apple juice begins with apple selection. Commercial juice manufacturers typically use processing-grade apples, which may differ from table apples but are chosen for:

- High juice yield

- Balanced sugar-to-acid ratio

- Strong apple aroma

- Consistent flesh structure

Incoming apples are inspected for:

- Ripeness and sugar content (Brix)

- Physical damage or decay

- Pesticide residue compliance

- Foreign materials (leaves, stones, metal)

Apples that fail quality standards are removed to protect final juice quality and processing equipment.

2. Washing and Sorting

Apples are thoroughly cleaned using bubble washers, spray washers, or drum washers to remove soil, dust, and surface contaminants.

After washing, apples pass through manual or optical sorting systems, where defective fruit is eliminated. Effective sorting reduces off-flavors, discoloration, and microbial risk later in the process.

3. Crushing and Milling

Clean apples are fed into a crusher or hammer mill, where they are broken into small pieces to release juice cells.

This step increases the surface area for juice extraction and prepares the mash for enzymatic treatment. The size of crushed particles is carefully controlled to balance juice yield and filtration efficiency.

4. Enzymatic Treatment

Apple mash naturally contains pectin, which traps juice and increases viscosity. To improve extraction and clarification, food-grade pectolytic enzymes are added.

Enzymatic treatment:

- Breaks down pectin structure

- Increases juice yield

- Improves clarity and filtration performance

- Reduces haze formation

This stage typically lasts 30–90 minutes under controlled temperature and pH conditions.

5. Juice Extraction (Pressing)

After enzymatic treatment, the apple mash is pressed using:

- Belt presses

- Hydraulic presses

- Screw presses

Modern belt presses are preferred for their:

- High extraction efficiency

- Continuous operation

- Gentle pressing to avoid bitterness from seeds

The extracted juice is collected, while pomace (apple solids) is discharged for by-product use such as animal feed or pectin production.

6. Clarification and Filtration

Raw apple juice contains fine solids that cause cloudiness. Depending on the desired product type, juice may be:

Clear Apple Juice

- Clarified using centrifugation, flotation, or membrane filtration

- Filtered to remove suspended particles

- Polished for high transparency

Cloudy Apple Juice

- Minimal clarification to preserve pulp

- Controlled stabilization to prevent separation

Clarification ensures visual consistency and shelf stability.

7. Deaeration and Oxidation Control

Apple juice is highly sensitive to oxygen, which can cause:

- Browning

- Flavor loss

- Nutrient degradation

To prevent oxidation, vacuum deaerators remove dissolved oxygen before thermal treatment. This step improves color retention and extends shelf life.

8. Pasteurization

Pasteurization is critical for food safety. Apple juice is heat-treated using:

- Plate heat exchangers

- Tubular heat exchangers

Common methods include:

- HTST (High Temperature Short Time) pasteurization

- UHT processing for shelf-stable products

Pasteurization eliminates harmful microorganisms while preserving taste when properly controlled.

9. Concentration (Optional)

For apple juice concentrate production, clarified juice is sent to vacuum evaporators.

Key advantages:

- Lower boiling temperature preserves aroma

- Efficient water removal

- Reduced storage and transportation costs

Concentrate is later reconstituted with water for consumer products.

10. Aseptic Filling and Packaging

After pasteurization (or concentration), apple juice is filled under hygienic conditions into:

- PET bottles

- Glass bottles

- Aseptic cartons

- Bulk aseptic bags

Aseptic filling prevents recontamination and enables long shelf life without preservatives.

11. Quality Control and Storage

Throughout production, manufacturers monitor:

- Brix value

- pH and acidity

- Color stability

- Microbiological safety

- Sensory quality

Finished apple juice is stored in temperature-controlled environments to maintain quality until distribution.

Apple juice manufacturing is a sophisticated process that combines mechanical extraction, biochemical treatment, thermal processing, and aseptic handling. Each stage directly influences flavor, clarity, yield, and shelf life.

Modern apple juice production is not simply about pressing apples—it is about precision, consistency, and strict quality control. Manufacturers who invest in advanced processing technology and hygienic design are best positioned to meet global food safety standards and market expectations.