Description

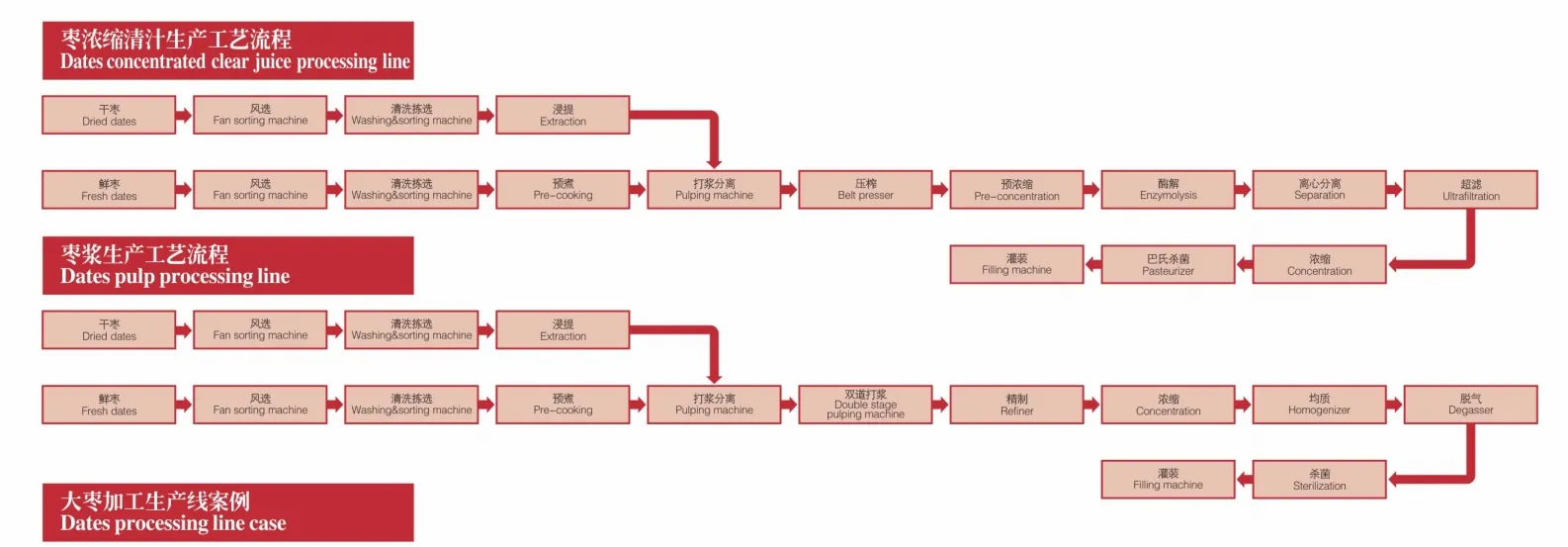

Dates Processing Line – Workflow

Dates Processing Line – Product Details

| Master Equipment-Dryer | Technical data | Qty | Unit |

| Burnner | Max output power 85kW Min output power 5kW | 1 | Set |

| Fan | 7.5kW, wind 1200m³/h | 2 | Piece |

| Moisture fan | 1.5kW | 1 | Piece |

| Electricity control box | 1 | Set | |

| Humidity sensor | 1 | Piece | |

| Temperature sensor | 3 | Piece | |

| Pressure switch | 2 | Piece |

Applications of Dates Processing Line

✔Dried whole jujubes

✔Pitted/sliced jujube products

✔Jujube powder/paste

✔Dates concentrated clear juice processing

Technical Advantages:

✔ Higher Profit Margins

-5–8% increased yield vs traditional methods

-30% energy savings with heat pump technology

✔ Premium Product Quality

-Natural color/flavor retention – No sulfur fumigation needed

-Uniform drying – Eliminates case hardening

✔Flexible Production

-Handles fresh/dried jujubes – Adjustable for different varieties

-Modular design – Scales from 500kg to 5T/day

✔ Certified Safety

-CE/FDA/ISO

-Stainless steel 304 construction

Key Features & Benefits of Dates Processing Line

✔Intelligent Cleaning & Sorting

-Multi-Stage Bubble Washing – Removes 99.8% of dust/pesticides

-AI Color & Defect Sorting – High-resolution cameras detect blemishes/size variations (accuracy >99.5%)

-Gentle Air-Drying Tunnel – Prepares jujubes for further processing

✔ Precision Pitting & Cutting

-Automatic Pitting Machine – Core removal without damaging flesh (pitting rate >95%)

-Adjustable Cutting System – Slices jujubes into halves, cubes, or strips

-Low-Oxygen Processing – Minimizes oxidation to preserve color

✔Smart Control System

-Self-Cleaning (CIP) – Meets food-grade hygiene standards

-Nitrogen Flushing System – Extends shelf life to 12–18 months