Description

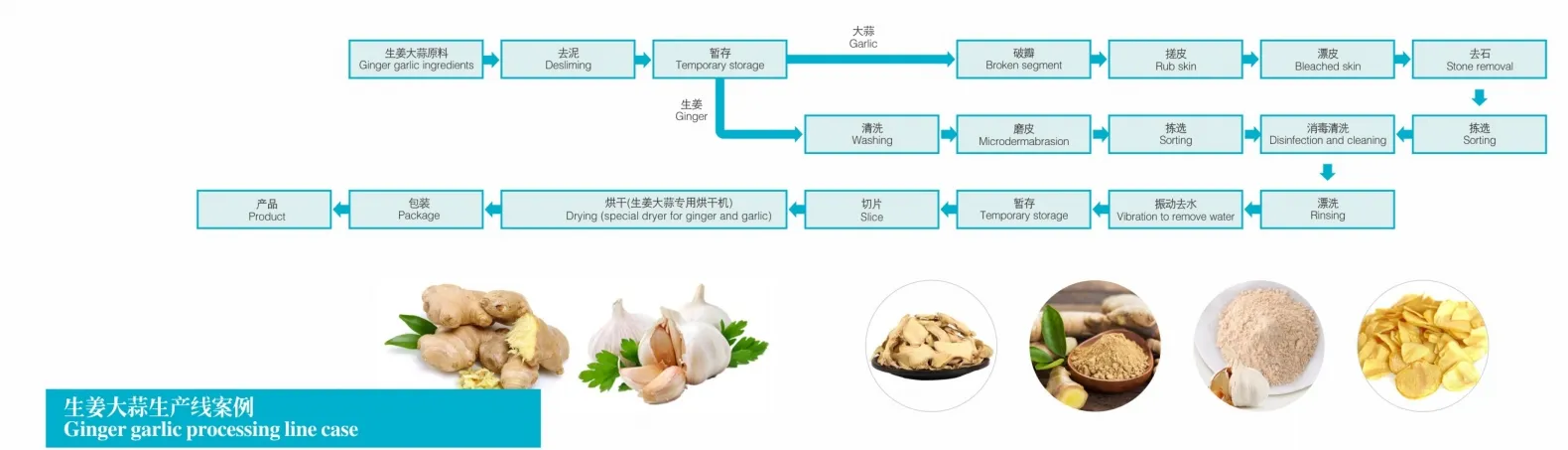

Ginger & Garlic Processing Line – Workflow

Ginger & Garlic Processing Line – Product Details

| Master Equipment-Dryer | Technical data | Qty | Unit |

| Burnner | Max output power 85kW Min output power 5kW | 1 | Set |

| Fan | 7.5kW, wind 1200m³/h | 2 | Piece |

| Moisture fan | 1.5kW | 1 | Piece |

| Electricity control box | 1 | Set | |

| Humidity sensor | 1 | Piece | |

| Temperature sensor | 3 | Piece | |

| Pressure switch | 2 | Piece |

Key Differentiators of Ginger & Garlic Processing Line

✔Dual-material compatibility – Process both ginger & garlic on same line

✔Modular design – Start with basic peeling, expand to oil extraction

✔Color-preservation tech – No chemical bleaching required

✔AI waste optimization – Maximizes byproduct value

Why Choose Our Ginger & Garlic Processing Line

1. High Efficiency & Cost Reduction

✔ ≤3% Peel Loss (vs 8-12% in traditional lines) → 67% higher raw material utilization

✔ 37.5% Energy Savings with heat pump/waste heat recovery systems

✔ 2-3 Operators Only (replaces 8-10 manual workers)

2. Optimal Nutrient Preservation

✔ ≥87% Retention of key bioactive compounds

✔ Low-Temperature Processing prevents thermal degradation

✔ Sulfur-Free treatment maintains natural color & nutrition

3. Unmatched Flexibility

✔ Dual-Material Switching in 30 minutes (garlic ⇄ ginger)

✔ Modular Design supports end-to-end production:

Fresh → Slices → Paste → Powder → Essential Oil

4. Smart Traceability

✔ IoT Real-Time Monitoring: Temperature/Humidity/Output

✔ Blockchain Tracking: Farm-to-factory data recording

5. Eco-Friendly Solutions

✔ Dry Peeling Option: Zero wastewater discharge

✔ Byproduct Valorization:

Peels → Animal feed

Residues → Organic fertilizer