Description

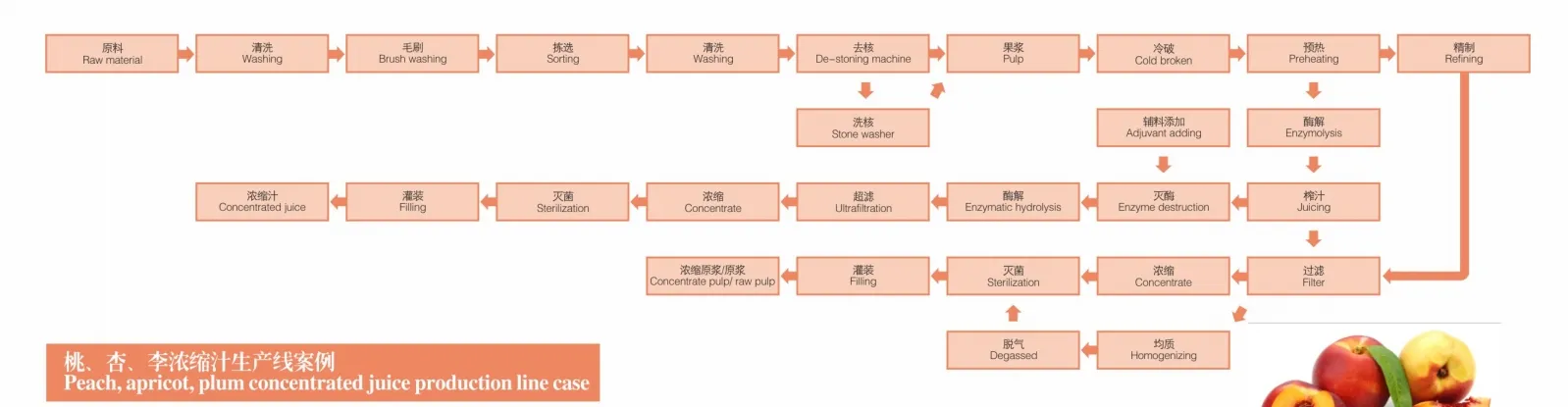

Peach Juice Production Line – Workflow

Peach Juice Production Line – Product Details

| Master Equipment-Fruit Stone Washer | KAXHJ-5 | KAXHJ-10 |

| Output(T/H) | 4~6 | 8~12 |

| Screen Aperture (MM) | 3、5、6、8、10 | 3、5、6、8、10、12 |

| Screen Diameter (MM) | Φ450 | Ф590 |

| c | 15 | 18.5 |

Key Processing Stages & Equipment of Peach Juice Production Line

1. Raw Material Handling & Preparation

Equipment:

-Optical Sorting Machine (AI-based, removes defective peaches with >99% accuracy)

-High-Pressure Washing System (removes dirt/pesticides with 30% less water usage)

-Destoning & Crushing Unit (gentle maceration to avoid bitterness from pits)

2. Juice Extraction & Clarification

Equipment:

-Decanter Centrifuge (separates pulp efficiently, reducing waste)

-Ultrafiltration (UF) System (removes haze-causing particles, improves clarity)

-Enzyme Treatment Tanks (pectinase/cellulase for higher extraction efficiency)

3. Evaporation & Concentration

Equipment:

-Five-Effect Falling Film Evaporator (operates at ≤65°C to preserve aroma)

Aroma Recovery Unit (captures volatile compounds like γ-decalactone for flavor enhancement)

4. Sterilization & Packaging

Equipment:

-UHT Sterilizer (137°C/4s, extends shelf life to 12+ months)

-Aseptic Bag-in-Box Filling (220kg bulk packaging, reduces oxidation risk)

Key Benefits of Peach Juice Production Line

✔ Higher Profitability (increased yield + lower energy costs)

✔ Premium Quality (better flavor, color, and nutrition)

✔ Sustainability (water recycling, reduced waste)

.webp)

.webp)