Description

Sorting Machine – Product Details

| Model | KAGDFX2-6 | KAGDFX2-8 | KAGDFX4-8 | KAGDFX4-10 |

| Grading Lanes (pcs) | 2 | 2 | 4 | 4 |

| Grade Capacity (pcs/s) | 7 | 7 | 7 | 7 |

| Outets (pcs) | 6+1 | 8+1 | 8+1 | 10+1 |

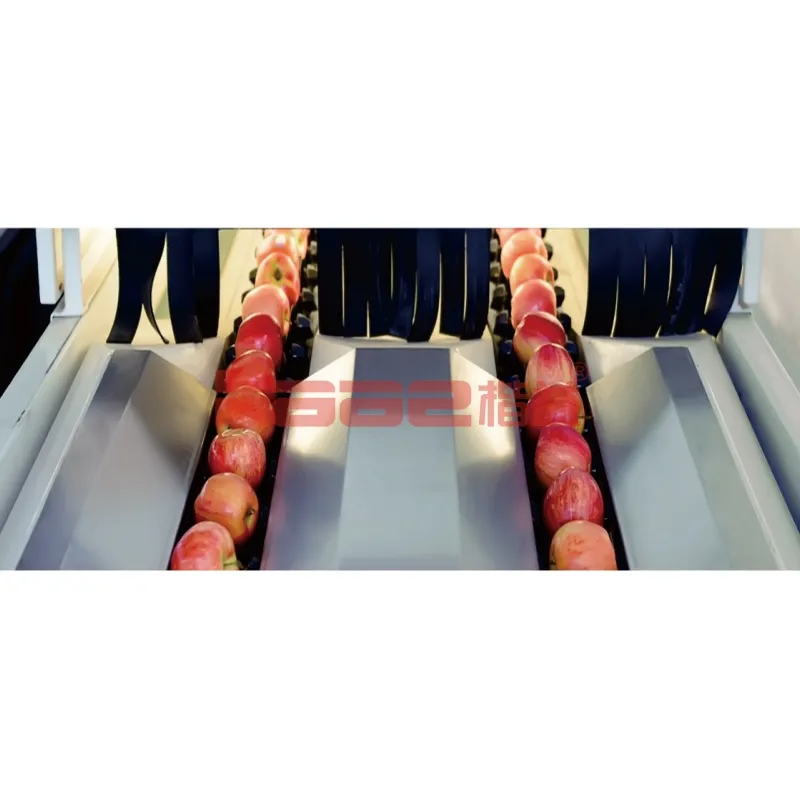

Suitable for sorting fruits and vegetable

Citrus, pear, persimmon, kiwi, mango, apricot, apple, pawpaw, plum, dates, greengage, dragon fruit, green pepper, tomato etc.

Technical Background of Sorting Machine

Automatic fruit sorting system as a modern fruit sorting technology. including on-line, cleaning, coating, drying, sorting, packing and other waler opera lions procedures, the sorting is both the key and the fastest growing in recent years, and the most used part of modern technology. This sorting line uses computer image processing to replace the artificial sorting, regardless of the shape of the fruit, size, color and external defects according to user requirements at the same time automatic sorting, greatly improving the work efficiency. Modern automatic image processing sorting system generally by the camera, no damage detection device, conveyor belt, computer, electrical control system and other components, in the fruit sorting, the fruit is located on the conveyor belt, the camera is arranged above and around the conveyor belt, and there are no damage detection devices installed in the conveyor belt. When the fruit through the camera to complete the general sorting operations, If you want to further understand the internal quality of the situation, through the non-invasive detection device to determine the sugar content and acidity indicators. The cleaning coating part of the fruit surface of the dust, pesticide residues and other foreign dirt washed and sprayed fruit in the fruit surface wax, polished by the brush roller, to extend the fruit preservation time.

Performance characteristics of Sorting Machine

✔Technically advances visual identification system with friendly operation screen.

✔Grading according to fruit size, shape and color.

✔Fruit color light, and size uniform after processing.

✔Conforming to relevant national standards.

✔Increasing added value of fruits products, reducing loss of juice, and increasing shelf life.

✔Compatible with packaging and labeling equipment to achieve complete automation of the whole processing line.