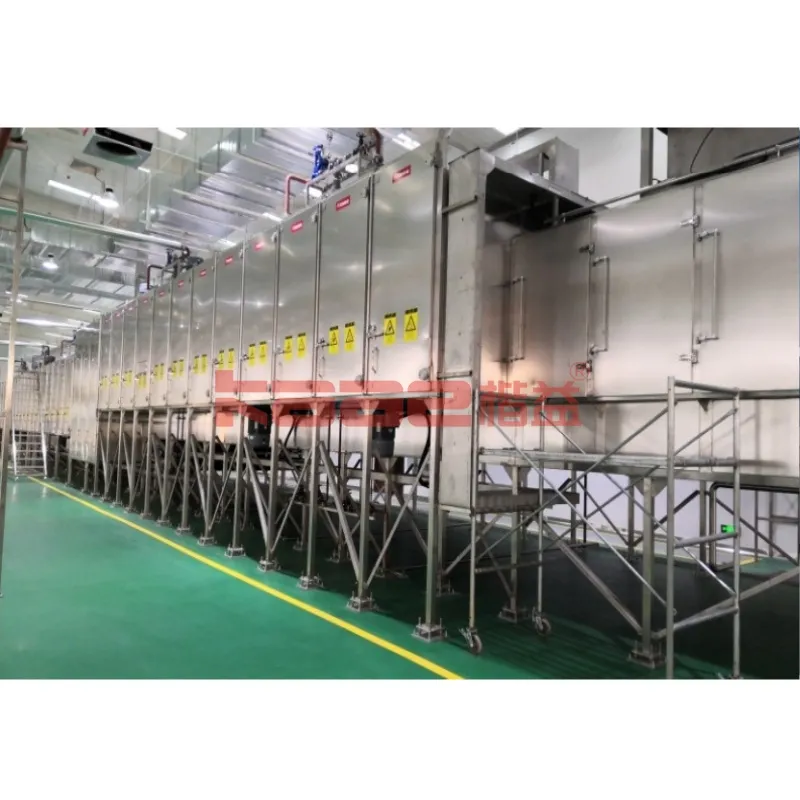

Tube bundle dryers, as highly efficient industrial drying equipment, play an indispensable role in numerous industries due to their superior energy-saving performance, diverse operating modes, powerful processing capacity, and wide applicability. Their applications are broad, including fermentation, starch, chemical, light industry, food and grain, feed, brewing, and alcohol industries.

Tube bundle dryers achieve material drying through counter-current or co-current operation modes, possessing high processing capacity and large moisture evaporation rate, effectively handling materials with high moisture content. This equipment is highly flexible, allowing adjustment of drying time according to material characteristics and moisture requirements, supporting continuous production (high level of automation) or intermittent operation (adapting to special production processes). Furthermore, the tube bundle dryer operates in a closed negative pressure environment, ensuring a clean and pollution-free working environment with low noise.

Structural Composition

Main Rotor System: The rotor consists of a tube bundle composed of hollow shafts at both ends, end caps, and numerous tubes. During operation, the rotor is supported by bearings at both ends; one end is fixed, while the other end can move freely to accommodate thermal expansion. The rotor is surrounded by lifting plates fixed to a support frame, used to turn the material and promote heat exchange.

The transmission system consists of a main motor and a reduction gear system, including two stages: a cycloidal pinwheel reducer and a gear reducer. The transmission system ensures stable rotor operation and provides sufficient torque to drive the large rotor.

The piping system, composed of regulating valves, metal hoses, rotary joints, etc., is responsible for conveying the heat medium (such as steam or hot oil) and ensuring its effective contact with the rotor’s interior for efficient heat transfer.

The exhaust and dust removal system uses an induced draft fan for exhaust and is equipped with a wet scrubber to recover hot water and dust. This not only reduces environmental pollution but also improves energy efficiency.

Application Areas

Tube bundle dryers are suitable for drying various loose materials, especially the following industries and materials:

Fermentation Industry: Corn germ, corn fiber

Starch Processing: Protein feed, protein powder

Chemical Industry: Distillers’ grains, marigolds

Light Industry: Wood chips, carrier materials for feed industry

Food Industry: Fish and shrimp by-products, bone meal

Agriculture: Rapeseed (non-seed use), rapeseed cake, pre-treated soybeans, pre-treated sunflower seeds, pre-treated other oilseeds and fruits

Fertilizer Production: Granular or powdered fertilizers

Mineral Processing: Powdered, granular, and fibrous loose materials such as inorganic minerals

Performance Characteristics

Complete Heat Exchange and Low Energy Consumption: The tube bundle dryer adopts a highly efficient heat exchange design, ensuring full contact between the material and the heat medium for thorough heat exchange. The choice between counter-current or co-current operation further reduces energy consumption, achieving high efficiency and energy saving.

Electricity Saving: Driven by a variable frequency motor, compared to traditional tube bundle dryers, electricity consumption can be reduced by more than 30%, significantly reducing operating costs. Fewer auxiliary equipment and smaller footprint: The compact equipment and rational process layout allow it to be placed in a single-story factory building, reducing construction costs and floor space requirements.

Thorough material mixing and no residue: The lifting plate design inside the drum ensures uniform material mixing and no residue, improving drying efficiency and product quality.

Reduced risk of weld cracking and leakage: The heat exchange tubes do not bear torque during drum rotation, reducing the risk of weld cracking and leakage caused by torque transmission, thus extending equipment lifespan. If leaks occur in the tubes, replacement is easy, simplifying maintenance.

Enhanced drum life: The drum wall thickness is 12-18 mm, while conventional tube bundle shells are typically 6 mm thick. Under the same wear and corrosion conditions, the drum life is significantly increased, extending the equipment’s service life.

Start-up with material: Allows start-up with material, shortening equipment preparation and downtime, and improving production efficiency.

Supports continuous or intermittent operation: Supports continuous operation (high degree of automation) or intermittent operation (adapting to special processes), meeting the needs of different production processes.