An industrial conveyor dryer removes moisture (typically water or other volatile components) from materials through heating, in order to obtain solid products with a specified moisture content.

I. Applications

The drying process consumes a large amount of thermal energy. To save energy, materials with high moisture content—such as suspensions or solutions containing solid substances—are often mechanically dewatered or evaporated by heating before being dried in an industrial conveyor dryer to obtain dry solids.

The purpose of drying is to meet the requirements of material use or further processing. For example, drying wood before mold making or woodworking prevents deformation of finished products; drying ceramic blanks before firing prevents cracking. In addition, dried materials are easier to store and transport—such as drying harvested grains below a certain moisture level to prevent mold. Because natural drying cannot meet modern production needs, various mechanized industrial conveyor dryers are becoming widely used.

During the drying process, both heat transfer and mass transfer (moisture evaporation) must be completed simultaneously. The surface vapor pressure of the material must be higher than that of the surrounding space, and the heat source temperature must be higher than the material temperature.

Heat is transferred from the high-temperature heat source to the wet material in various ways, causing moisture on the material surface to vaporize and escape. This creates a moisture gradient between the surface and interior of the material. Internal moisture diffuses to the surface and continues to evaporate, progressively reducing overall moisture content and completing the drying process.

The drying rate depends on both surface evaporation rate and internal moisture diffusion rate. Generally, the early stage of drying is controlled by surface evaporation. As long as external drying conditions remain constant, both drying rate and material surface temperature stay stable—this is called the constant-rate drying stage. After the material reaches a certain low moisture content, internal moisture diffusion becomes slower and lower than surface evaporation. At this stage, the drying rate decreases with moisture reduction—this is the falling-rate drying stage.

II. Classification

Industrial conveyor dryers can be classified according to operating process, operating pressure, heating method, material movement, or structural design.

1. By operating process:

- Batch (intermittent) industrial conveyor dryers

- Continuous industrial conveyor dryers

2. By operating pressure:

- Atmospheric industrial conveyor dryers

- Vacuum industrial conveyor dryers

Vacuum operation lowers vapor pressure, accelerates drying, reduces boiling point and material drying temperature, and prevents vapor escape. Therefore, vacuum dryers are suitable for heat-sensitive, easily oxidized, explosive, toxic materials, or those requiring vapor recovery.

3. By heating method:

- Convective (direct) industrial conveyor dryers

Hot drying medium directly contacts the material, transferring heat by convection and removing moisture. - Conductive (indirect) industrial conveyor dryers

Heat is transferred through a metal wall. Moisture is removed by vacuum suction, purging gas, or condensation. These have no contact drying medium, high thermal efficiency, and no product contamination, but have limited capacity and more complex structure—often operated under vacuum. - Radiation industrial conveyor dryers

Use electromagnetic radiation absorbed by material surfaces to generate heat. - Dielectric industrial conveyor dryers

Use high-frequency electric fields to produce internal heating within the material.

4. By material movement:

- Fixed-bed industrial conveyor dryers

- Agitated dryers

- Spray dryers

- Combined-type dryers

5. By structure:

Industrial conveyor dryers include:

- Box-type dryers

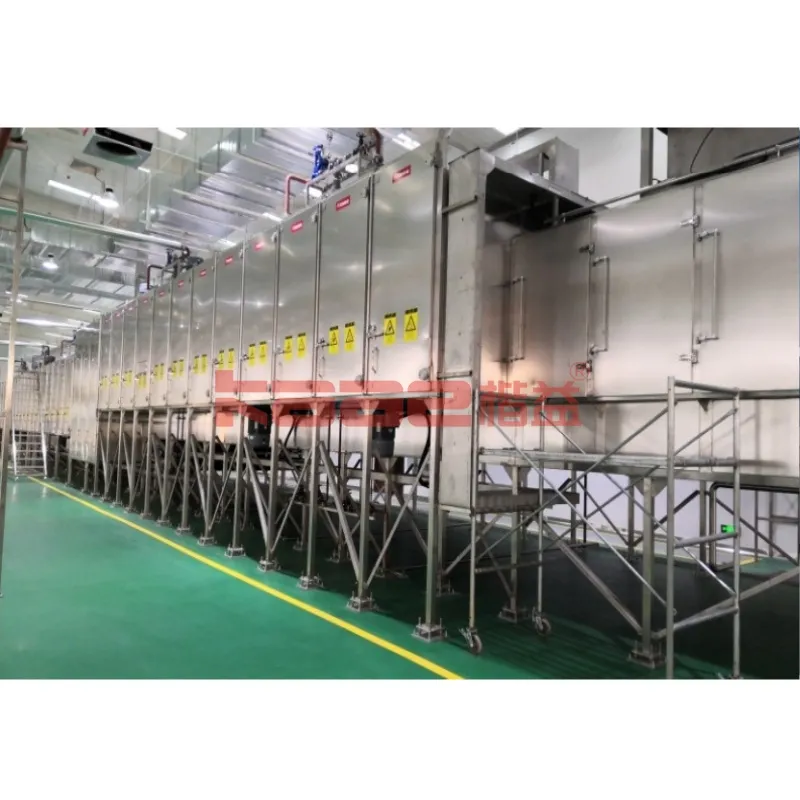

- Conveyor-type dryers

- Drum dryers

- Vertical dryers

- Mechanical agitation dryers

- Rotary dryers

- Fluidized-bed dryers

- Airflow dryers

- Vibrating dryers

- Spray dryers

- Combined-structure dryers